China High quality Super duplex stainless steel electrode Products – Precision stainless steel seamless steel tube – Future Metal

China High quality Super duplex stainless steel electrode Products – Precision stainless steel seamless steel tube – Future Metal Detail:

Product features

High precision, no cutting, precision up to ±0.03mm, smooth surface, roughness above 8; tube wall is thin and uniform, corrosion resistance, high temperature resistance, high pressure resistance.

The specific varieties are

1.Stainless steel ultra-thin-walled seamless steel pipe outer diameter: 7-80mm, wall thickness: 0.08-0.3mm。

Technical standard: GB/T 3089-2008 “Stainless acid-resistant steel extremely thin-walled seamless steel pipe”。

Widely used in national defense Industries such as scientific research, aerospace, instrumentation, chemical industry, machinery and pneumatic components.

2.Outer diameter of stainless steel capillary tube: 0.32-4.8mm, wall thickness: 0.1-1mm.

Technical standard: GB/T3090-2000 “Stainless Steel Small Diameter Steel Pipe” Product features: small diameter, high precision, suitable for precision instrumentation, Electronic appliances, automation instruments and other industries.

3.Outer diameter of seamless stainless steel pipe: 5-80mm, wall thickness 0.5-4mm.

Technical standard: GB/T 14975-2012 “Stainless steel seamless steel pipe for structure”, GB/T 14976-2012 “Stainless steel seamless steel pipe for fluid transportation” Steel pipe”.

Suitable for machinery, chemical industry, pneumatic components, cylinder liners, electric heating appliances and other industries.

The most important thing in the production of precision stainless steel pipes is welding, inner weld leveling and pickling process. The welding process in the production process is very technical. The welding seam must be smooth, and there must be no welding defects such as pores and slag, and the defects should be repaired in time; when the workpiece is required to be sealed and continuously welded, it is required that there should be no pores and trachoma at the weld. The internal leveling technology of the weld directly affects the anti-corrosion performance and quality of the inner wall of the pipe; and the time, temperature, and solution concentration in the pickling process need to be strictly controlled, otherwise inclusions will accumulate and cause corrosion of the pipe fittings, and the inclusions will fall off in the later period. Small pit-shaped defects are formed on the surface.

Technology

Technology will have a great impact on products, so production technology determines quality. According to the most basic standards, the precision of stainless steel precision tubes can basically reach ±0.05mm~±0.15mm. The tolerance range here is also a brief explanation. Generally, the tolerance range of pipes with relatively small diameter and thinner wall thickness is basically ±0.05mm. Relatively speaking, the tolerance range of stainless steel precision pipes with larger diameters is basically ±0.05mm~±0.15mm.

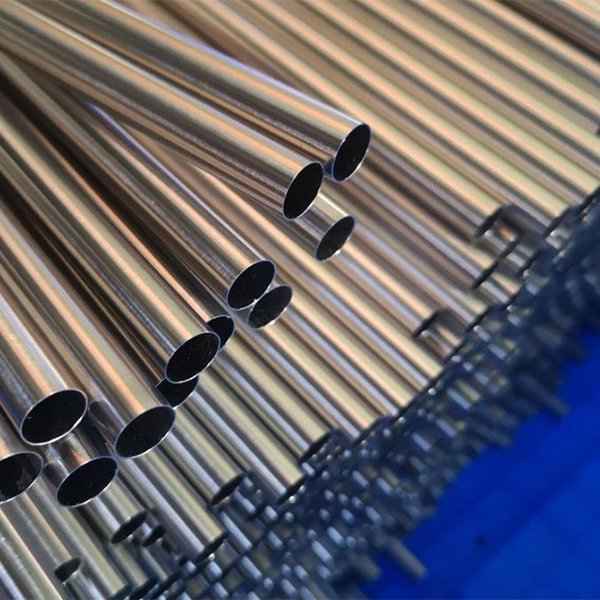

Product Display

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" as well as the theory of "quality the basic, believe in the 1st and management the advanced" for China High quality Super duplex stainless steel electrode Products – Precision stainless steel seamless steel tube – Future Metal , The product will supply to all over the world, such as: Chile, Johor, Benin, So We also continuously function. we, focuse on high quality, and are conscious of the importance of environmental protection, most of the merchandise are pollution-free, environmentally friendly products, reuse on the solution. We've Updated our catalog, which introduces our organization. n detail and covers the primary items we provide at present, You may also visit our web-site, which involves our most recent product line. We look forward to reactivating our company connection.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.