With this motto in mind, we have become one of the most technologically innovative, cost-efficient, and price-competitive manufacturers for China Supplier China S355jh 48 Inch Black Iron Pipe Welded Pipe Tube Carbon Seamless Steel Pipe, Looking to the future, a long way to go, constantly striving to become the all staff with full enthusiasm, one hundred times the confidence and put our company built a beautiful environment, advanced products, quality first-class modern enterprise and work hard!

With this motto in mind, we have become one of the most technologically innovative, cost-efficient, and price-competitive manufacturers for China Carbon Steel Pipe, Steel Tube, With the development of the society and economy, our company will continue the “loyalty, dedication, efficiency, innovation” spirit of enterprise, and we’ll always adhere to the management idea of “would rather lose gold, do not lose customers heart”. We’ll serve the domestic and foreign businessmen with sincere dedication, and allow us to create bright future together with you!

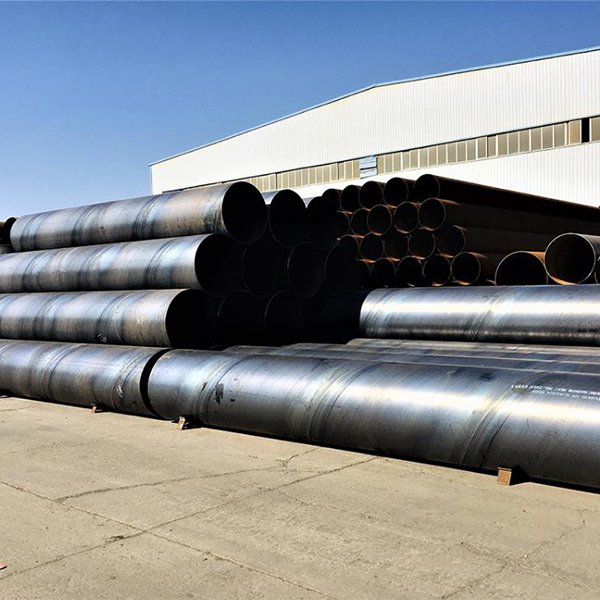

SSAW Steel Pipe

| Outside Diameter OD |

219mm-3500mm |

| Wall Thickness |

1.5mm-25mm |

| Length |

3-18M |

| Surface |

Bare, Lightly Oiling, Black Painting, Anti-corrosion Coating (FBE / 2PE / 3PE) |

| Packing |

In Bulk, Ends Protector on Both Sides, Waterproof Materials Wrapped |

| Application |

water pipe, steel piling, oil and gas pipes, steel pipelines , etc. |

Product specifications

| Classfication |

Standard |

Main Products |

| Steel Pipe for Fluid Service |

GB/T 14291 |

Welded pipe for mine fluid sevice |

| GB/T 3091 |

Welded pipe for low pressure fluid service |

| SY/T 5037 |

Spirally submerged arc welded steel pipe for pipelines for low pressure fluid service |

| ASTM A53 |

Black and hot-hipped galvanized welded and seamless steel pipe |

| BS EN10217-2 |

Welded steel tybes for pressure purposes – delivery technical conditions – part2: Electric welded non- alloy and alloy steel tubes with specified elevated temperature properties |

| BS EN10217-5 |

Welded steel tybes for pressure purposes – delivery technical conditions – part5: submerged arc welded non-alloy and alloy steel tubes with specified elevated temperature properties |

| Steel Pipe for Ordinary Structure |

GB/T 13793 |

Longitudinally electric resistance welded steel pipe |

| SY/T 5040 |

Spirally submerged arc welded steel pipe piles |

| ASTM A252 |

Welded and seamless steel pipe piles |

| BS EN10219-1 |

Cold formed welded structural hollow sections of non-alloy and fine grain steels – part1: Technical delivert conditions |

| BS EN10219-2 |

Cold formed welded structural hollow sections of non-alloy and fine grain steels – part2: tolerances dimmsions and sectional properties |

| Line Pipe |

GB/T 9711.1 |

Steel pipe for pipeline transportation system of petroleum and natural gas industries(Class A steel pipe) |

| GB/T 9711.2 |

Steel pipe for pipeline transportation system of petroleum and natural gas industries(Class B steel pipe) |

| API 5L PSL1/2 |

Line pipe |

| Casing |

API 5CT/ ISO 11960 PSL1 |

Steel pipe for use as casing or tubing for wells of petroleum and natural gas industries |

Chemical Analysis and Mechanical Properties

| Standard |

Grade |

Chemical Composition(max)% |

Mechanical Properties(min) |

| C |

Si |

Mn |

P |

S |

Tensile Strength(Mpa) |

Yield Strength(Mpa) |

| API 5CT |

h40 |

- |

- |

- |

- |

0.030 |

417 |

417 |

| J55 |

- |

- |

- |

- |

0.030 |

517 |

517 |

| K55 |

- |

- |

- |

- |

0.030 |

655 |

655 |

| API 5L PSL1 |

A |

0.22 |

- |

0.90 |

0.030 |

0.030 |

335 |

335 |

| B |

0.26 |

- |

1.20 |

0.030 |

0.030 |

415 |

415 |

| X42 |

0.26 |

- |

1.30 |

0.030 |

0.030 |

415 |

415 |

| X46 |

0.26 |

- |

1.40 |

0.030 |

0.030 |

435 |

435 |

| X52 |

0.26 |

- |

1.40 |

0.030 |

0.030 |

460 |

460 |

| X56 |

0.26 |

- |

1.40 |

0.030 |

0.030 |

490 |

490 |

| X60 |

0.26 |

- |

1.40 |

0.030 |

0.030 |

520 |

520 |

| X65 |

0.26 |

- |

1.45 |

0.030 |

0.030 |

535 |

535 |

| X70 |

0.26 |

- |

1.65 |

0.030 |

0.030 |

570 |

570 |

| API 5L PSL2 |

B |

0.22 |

0.45 |

1.20 |

0.025 |

0.015 |

415 |

415 |

| X42 |

0.22 |

0.45 |

1.30 |

0.025 |

0.015 |

415 |

415 |

| X46 |

0.22 |

0.45 |

1.40 |

0.025 |

0.015 |

435 |

435 |

| X52 |

0.22 |

0.45 |

1.40 |

0.025 |

0.015 |

460 |

460 |

| X56 |

0.22 |

0.45 |

1.40 |

0.025 |

0.015 |

490 |

490 |

| X60 |

0.12 |

0.45 |

1.60 |

0.025 |

0.015 |

520 |

520 |

| X65 |

0.12 |

0.45 |

1.60 |

0.025 |

0.015 |

535 |

535 |

| X70 |

0.12 |

0.45 |

1.70 |

0.025 |

0.015 |

570 |

570 |

| X80 |

0.12 |

0.45 |

1.85 |

0.025 |

0.015 |

625 |

625 |

| GB/T 9711.1 |

L210 |

- |

- |

0.90 |

0.030 |

0.030 |

335 |

335 |

| L245 |

- |

- |

1.15 |

0.030 |

0.030 |

415 |

415 |

| L290 |

- |

- |

1.25 |

0.030 |

0.030 |

415 |

415 |

| L320 |

- |

- |

1.25 |

0.030 |

0.030 |

435 |

435 |

| L360 |

- |

- |

1.25 |

0.030 |

0.030 |

460 |

460 |

| L390 |

- |

- |

1.35 |

0.030 |

0.030 |

490 |

490 |

| L415 |

0.26 |

- |

1.35 |

0.030 |

0.030 |

520 |

520 |

| L450 |

0.26 |

- |

1.40 |

0.030 |

0.030 |

535 |

535 |

| L485 |

0.23 |

- |

1.60 |

0.030 |

0.030 |

570 |

570 |

| GB/T3091/ SY/T503 |

Q195 |

0.12 |

0.30 |

0.50 |

0.035 |

0.040 |

315 |

315 |

| Q215B |

0.15 |

0.35 |

1.20 |

0.045 |

0.045 |

335 |

335 |

| Q235B |

0.20 |

0.35 |

1.40 |

0.045 |

0.045 |

370 |

370 |

| Q345B |

0.20 |

0.50 |

1.70 |

0.035 |

0.035 |

470 |

470 |

| ASTM A53 |

A |

0.25 |

0.10 |

0.95 |

0.050 |

0.045 |

330 |

330 |

| B |

0.30 |

0.10 |

1.20 |

0.050 |

0.045 |

415 |

415 |

| ASTM A252 |

1 |

- |

- |

- |

0.050 |

- |

345 |

345 |

| 2 |

- |

- |

- |

0.050 |

- |

414 |

414 |

| 3 |

- |

- |

- |

0.050 |

- |

455 |

455 |

| EN10217-1 |

P195TR1 |

0.13 |

0.35 |

0.70 |

0.025 |

0.020 |

320 |

320 |

| P195TR2 |

0.13 |

0.35 |

0.70 |

0.025 |

0.020 |

320 |

320 |

| P235TR1 |

0.16 |

0.35 |

1.20 |

0.025 |

0.020 |

360 |

360 |

| P235TR2 |

0.16 |

0.35 |

1.20 |

0.025 |

0.020 |

360 |

360 |

| P265TR1 |

0.20 |

0.40 |

1.40 |

0.025 |

0.020 |

410 |

410 |

| P265TR2 |

0.20 |

0.40 |

1.40 |

0.025 |

0.020 |

410 |

410 |

| EN10217-2 |

P195GH |

0.13 |

0.35 |

0.70 |

0.025 |

0.020 |

320 |

320 |

| P235GH |

0.16 |

0.35 |

1.20 |

0.025 |

0.020 |

360 |

360 |

| P265GH |

0.20 |

0.40 |

1.40 |

0.025 |

0.020 |

410 |

410 |

| EN10217-5 |

P235GH |

0.16 |

0.35 |

1.20 |

0.025 |

0.020 |

360 |

360 |

| P265GH |

0.20 |

0.40 |

1.40 |

0.025 |

0.020 |

410 |

410 |

| EN10219-1 |

S235JRH |

0.17 |

- |

1.40 |

0.040 |

0.040 |

360 |

360 |

| S275JOH |

0.20 |

- |

1.50 |

0.035 |

0.035 |

410 |

410 |

| S275J2H |

0.20 |

- |

1.50 |

0.030 |

0.030 |

410 |

410 |

| S355JOH |

0.22 |

0.55 |

1.60 |

0.035 |

0.035 |

470 |

470 |

| S355J2H |

0.22 |

0.55 |

1.60 |

0.030 |

0.030 |

470 |

470 |

| S355K2H |

0.22 |

0.55 |

1.60 |

0.030 |

0.030 |

470 |

470 |

Tolerance of Outside Diameter and Wall Thickness

| Standard |

Tolerance of Pipe Body |

Tolerance of Pipe End |

Tolerance of Wall Thickness |

| Out Diameter |

Tolerance |

Out Diameter |

Tolerance |

| GB/T3091 |

OD≤48.3mm |

≤±0.5 |

OD≤48.3mm |

- |

≤±10% |

| 48.3<od≤273.1mm |

≤±1.0% |

48.3<od≤273.1mm< span=”" style=”padding: 0px; margin: 0px;”> |

- |

| 273.1<od≤508mm |

≤±0.75% |

273.1<od≤508mm< span=”" style=”padding: 0px; margin: 0px;”> |

-0.8~+2.4 |

| OD>508mm |

≤±1.0% |

OD>508mm |

-0.8~+3.2 |

| GB/T9711.1 |

OD≤48.3mm |

-0.79~+0.41 |

- |

- |

OD≤73 |

-12.5%~+20% |

| 60.3<od≤457mm |

≤±0.75% |

OD≤273.1mm |

-0.4~+1.59 |

88.9≤OD≤457 |

-12.5%~+15% |

| 508<od≤941mm |

≤±1.0% |

OD≥323.9 |

-0.79~+2.38 |

OD≥508 |

-10.0%~+17.5% |

| OD>941mm |

≤±1.0% |

- |

- |

- |

- |

| GB/T9711.2 |

60<od≤610mm |

±0.75%D~±3mm |

60<od≤610mm |

±0.5%D~±1.6mm |

4mm<wt<25mm |

±12.5%T~±15.0%T |

| 610<od≤1430mm |

±0.5%D~±4mm |

610<od≤1430mm |

±0.5%D~±1.6mm |

WT≥25mm |

-3.00mm~+3.75mm |

| OD>1430mm |

- |

OD>1430mm |

- |

- |

-10.0%~+17.5% |

| SY/T5037 |

OD<508mm |

≤±0.75% |

OD<508mm |

≤±0.75% |

OD<508mm |

≤±12.5% |

| OD≥508mm |

≤±1.00% |

OD≥508mm |

≤±0.50% |

OD≥508mm |

≤±10.0% |

| API 5L PSL1/PSL2 |

OD<60.3 |

-0.8mm~+0.4mm |

OD≤168.3 |

-0.4mm~+1.6mm |

WT≤5.0 |

≤±0.5 |

| 60.3≤OD≤168.3 |

≤±0.75% |

168.3<od≤610 |

≤±1.6mm |

5.0<wt<15.0 |

≤±0.1T |

| 168.3<od≤610 |

≤±0.75% |

610<od≤1422 |

≤±1.6mm |

T≥15.0 |

≤±1.5 |

| 610<od≤1422 |

≤±4.0mm |

OD>1422 |

- |

- |

- |

| OD>1422 |

- |

- |

- |

- |

- |

| API 5CT |

OD<114.3 |

≤±0.79mm |

OD<114.3 |

≤±0.79mm |

≤-12.5% |

| OD≥114.3 |

-0.5%~1.0% |

OD≥114.3 |

-0.5%~1.0% |

≤-12.5% |

| ASTM A53 |

≤±1.0% |

≤±1.0% |

≤-12.5% |

| ASTM A252 |

≤±1.0% |

≤±1.0% |

≤-12.5% |

Product Display

With this motto in mind, we have become one of the most technologically innovative, cost-efficient, and price-competitive manufacturers for China Supplier China S355jh 48 Inch Black Iron Pipe Welded Pipe Tube Carbon Seamless Steel Pipe, Looking to the future, a long way to go, constantly striving to become the all staff with full enthusiasm, one hundred times the confidence and put our company built a beautiful environment, advanced products, quality first-class modern enterprise and work hard!

China Supplier China Carbon Steel Pipe, Steel Tube, With the development of the society and economy, our company will continue the “loyalty, dedication, efficiency, innovation” spirit of enterprise, and we’ll always adhere to the management idea of “would rather lose gold, do not lose customers heart”. We’ll serve the domestic and foreign businessmen with sincere dedication, and allow us to create bright future together with you!

Previous:

China Supplier China S355jh 48 Inch Black Iron Pipe Welded Pipe Tube Carbon Seamless Steel Pipe

Next:

astm a106 low carbon steel pipe