Famous color coated galvanized roll Products – 304 stainless steel mirror plate – Future Metal

Famous color coated galvanized roll Products – 304 stainless steel mirror plate – Future Metal Detail:

304 stainless steel mirror plate

The mirror panel is also called 8K board, which is polished on the surface of the stainless steel plate by polishing equipment with abrasive liquid to make the surface brightness as clear as a mirror.

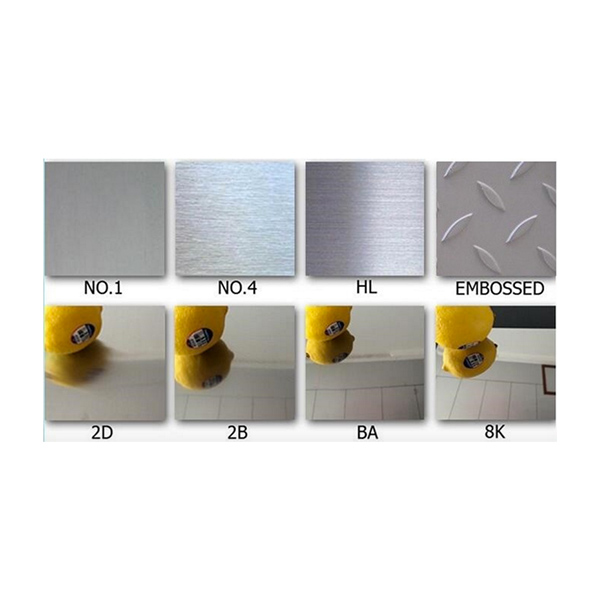

The stainless steel material is ground and polished, and the surface is smooth and mirror-like stainless steel plate. There are 2B, BA, ordinary surface, 8K surface, and 8K surface is the best.

Uses: stainless steel series products such as building decoration, elevator decoration, industrial decoration, facility decoration, etc.

We supply 316 stainless steel mirror panels, 316L stainless steel mirror panels, 304 stainless steel mirror panels, 301 stainless steel mirror panels, 201 stainless steel mirror panels, etc.

The principle of stainless steel plate production is that the stainless steel raw material is polished by the polishing equipment on the surface of the steel plate with a polishing liquid, so that the surface of the plate is flat and the brightness is as clear as a mirror. Stainless steel mirror panel products are widely used in decoration projects such as building decoration, elevator decoration, industrial decoration, and facility decoration.

The process of stainless steel mirror panel processing can be divided into two methods: normal grinding and fine grinding. Which of these two processing methods produces a better mirror effect? And this must be judged by looking at the brightness of the mirror surface, and the blisters and grinding heads on the surface of the plate must be less.

Generally speaking, stainless steel plates are processed on a polishing machine. The slower the traveling speed, the more the number of grinding groups, and this effect will be very good; when stainless steel plates are processed by polishing equipment, the first thing to do is to correct The plate is sanded, and then the stainless steel plate is put into the grinding fluid, which needs to be ground through 8 groups of grinding heads with different thicknesses. The grinding process is basically the surface treatment of the stainless steel plate. There is no depth in this process. This step is mainly for Remove the oxide layer on the surface of the stainless steel plate.

After finishing the above process, it can be washed and dried. The color stainless steel mirror panel is colored on the basis of the stainless steel mirror panel. Now the high-end color stainless steel mirror panel is processed by vacuum ion plating technology. It is even possible to perform pattern etching on the mirror panel, and various patterns and styles of pattern etching plates can be obtained.

Product detail pictures:

Related Product Guide:

We're also concentrating on improving the things administration and QC program to ensure we could maintain terrific gain from the fiercely-competitive company for Famous color coated galvanized roll Products – 304 stainless steel mirror plate – Future Metal , The product will supply to all over the world, such as: Kazakhstan, UK, Palestine, we are fully determined to control the whole supply chain so as to provide quality products at competitive price in a timely manner. We are keeping up with the advanced techniques, growing through creating more values for our clients and society.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!