stainless steel pipe company Manufacturer – SSAW Carbon SteelPipe Welded Steel Pipe – Future Metal

stainless steel pipe company Manufacturer – SSAW Carbon SteelPipe Welded Steel Pipe – Future Metal Detail:

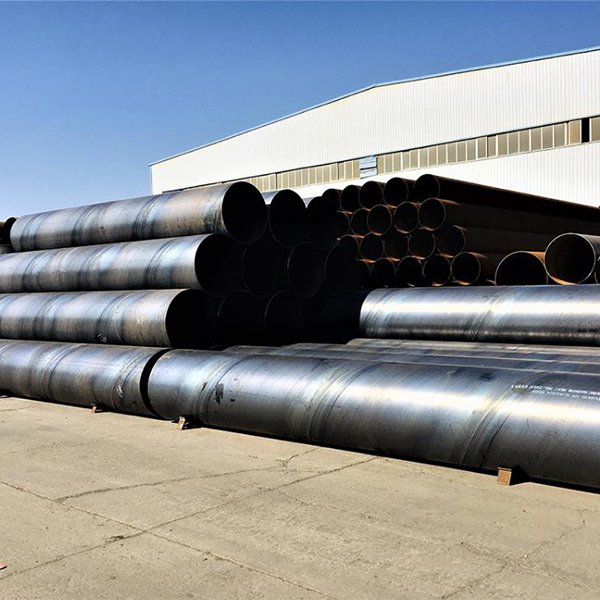

SSAW Steel Pipe

| Outside Diameter OD | 219mm-3500mm |

| Wall Thickness | 1.5mm-25mm |

| Length | 3-18M |

| Surface | Bare, Lightly Oiling, Black Painting, Anti-corrosion Coating (FBE / 2PE / 3PE) |

| Packing | In Bulk, Ends Protector on Both Sides, Waterproof Materials Wrapped |

| Application | water pipe, steel piling, oil and gas pipes, steel pipelines , etc. |

Product specifications

| Classfication | Standard | Main Products |

| Steel Pipe for Fluid Service | GB/T 14291 | Welded pipe for mine fluid sevice |

| GB/T 3091 | Welded pipe for low pressure fluid service | |

| SY/T 5037 | Spirally submerged arc welded steel pipe for pipelines for low pressure fluid service | |

| ASTM A53 | Black and hot-hipped galvanized welded and seamless steel pipe | |

| BS EN10217-2 | Welded steel tybes for pressure purposes – delivery technical conditions – part2: Electric welded non- alloy and alloy steel tubes with specified elevated temperature properties | |

| BS EN10217-5 | Welded steel tybes for pressure purposes – delivery technical conditions – part5: submerged arc welded non-alloy and alloy steel tubes with specified elevated temperature properties | |

| Steel Pipe for Ordinary Structure | GB/T 13793 | Longitudinally electric resistance welded steel pipe |

| SY/T 5040 | Spirally submerged arc welded steel pipe piles | |

| ASTM A252 | Welded and seamless steel pipe piles | |

| BS EN10219-1 | Cold formed welded structural hollow sections of non-alloy and fine grain steels – part1: Technical delivert conditions | |

| BS EN10219-2 | Cold formed welded structural hollow sections of non-alloy and fine grain steels – part2: tolerances dimmsions and sectional properties | |

| Line Pipe | GB/T 9711.1 | Steel pipe for pipeline transportation system of petroleum and natural gas industries(Class A steel pipe) |

| GB/T 9711.2 | Steel pipe for pipeline transportation system of petroleum and natural gas industries(Class B steel pipe) | |

| API 5L PSL1/2 | Line pipe | |

| Casing | API 5CT/ ISO 11960 PSL1 | Steel pipe for use as casing or tubing for wells of petroleum and natural gas industries |

Chemical Analysis and Mechanical Properties

| Standard | Grade | Chemical Composition(max)% | Mechanical Properties(min) | |||||

| C | Si | Mn | P | S | Tensile Strength(Mpa) | Yield Strength(Mpa) | ||

| API 5CT | h40 | - | - | - | - | 0.030 | 417 | 417 |

| J55 | - | - | - | - | 0.030 | 517 | 517 | |

| K55 | - | - | - | - | 0.030 | 655 | 655 | |

| API 5L PSL1 | A | 0.22 | - | 0.90 | 0.030 | 0.030 | 335 | 335 |

| B | 0.26 | - | 1.20 | 0.030 | 0.030 | 415 | 415 | |

| X42 | 0.26 | - | 1.30 | 0.030 | 0.030 | 415 | 415 | |

| X46 | 0.26 | - | 1.40 | 0.030 | 0.030 | 435 | 435 | |

| X52 | 0.26 | - | 1.40 | 0.030 | 0.030 | 460 | 460 | |

| X56 | 0.26 | - | 1.40 | 0.030 | 0.030 | 490 | 490 | |

| X60 | 0.26 | - | 1.40 | 0.030 | 0.030 | 520 | 520 | |

| X65 | 0.26 | - | 1.45 | 0.030 | 0.030 | 535 | 535 | |

| X70 | 0.26 | - | 1.65 | 0.030 | 0.030 | 570 | 570 | |

| API 5L PSL2 | B | 0.22 | 0.45 | 1.20 | 0.025 | 0.015 | 415 | 415 |

| X42 | 0.22 | 0.45 | 1.30 | 0.025 | 0.015 | 415 | 415 | |

| X46 | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 | 435 | 435 | |

| X52 | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 | 460 | 460 | |

| X56 | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 | 490 | 490 | |

| X60 | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 | 520 | 520 | |

| X65 | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 | 535 | 535 | |

| X70 | 0.12 | 0.45 | 1.70 | 0.025 | 0.015 | 570 | 570 | |

| X80 | 0.12 | 0.45 | 1.85 | 0.025 | 0.015 | 625 | 625 | |

| GB/T 9711.1 | L210 | - | - | 0.90 | 0.030 | 0.030 | 335 | 335 |

| L245 | - | - | 1.15 | 0.030 | 0.030 | 415 | 415 | |

| L290 | - | - | 1.25 | 0.030 | 0.030 | 415 | 415 | |

| L320 | - | - | 1.25 | 0.030 | 0.030 | 435 | 435 | |

| L360 | - | - | 1.25 | 0.030 | 0.030 | 460 | 460 | |

| L390 | - | - | 1.35 | 0.030 | 0.030 | 490 | 490 | |

| L415 | 0.26 | - | 1.35 | 0.030 | 0.030 | 520 | 520 | |

| L450 | 0.26 | - | 1.40 | 0.030 | 0.030 | 535 | 535 | |

| L485 | 0.23 | - | 1.60 | 0.030 | 0.030 | 570 | 570 | |

| GB/T3091/ SY/T503 | Q195 | 0.12 | 0.30 | 0.50 | 0.035 | 0.040 | 315 | 315 |

| Q215B | 0.15 | 0.35 | 1.20 | 0.045 | 0.045 | 335 | 335 | |

| Q235B | 0.20 | 0.35 | 1.40 | 0.045 | 0.045 | 370 | 370 | |

| Q345B | 0.20 | 0.50 | 1.70 | 0.035 | 0.035 | 470 | 470 | |

| ASTM A53 | A | 0.25 | 0.10 | 0.95 | 0.050 | 0.045 | 330 | 330 |

| B | 0.30 | 0.10 | 1.20 | 0.050 | 0.045 | 415 | 415 | |

| ASTM A252 | 1 | - | - | - | 0.050 | - | 345 | 345 |

| 2 | - | - | - | 0.050 | - | 414 | 414 | |

| 3 | - | - | - | 0.050 | - | 455 | 455 | |

| EN10217-1 | P195TR1 | 0.13 | 0.35 | 0.70 | 0.025 | 0.020 | 320 | 320 |

| P195TR2 | 0.13 | 0.35 | 0.70 | 0.025 | 0.020 | 320 | 320 | |

| P235TR1 | 0.16 | 0.35 | 1.20 | 0.025 | 0.020 | 360 | 360 | |

| P235TR2 | 0.16 | 0.35 | 1.20 | 0.025 | 0.020 | 360 | 360 | |

| P265TR1 | 0.20 | 0.40 | 1.40 | 0.025 | 0.020 | 410 | 410 | |

| P265TR2 | 0.20 | 0.40 | 1.40 | 0.025 | 0.020 | 410 | 410 | |

| EN10217-2 | P195GH | 0.13 | 0.35 | 0.70 | 0.025 | 0.020 | 320 | 320 |

| P235GH | 0.16 | 0.35 | 1.20 | 0.025 | 0.020 | 360 | 360 | |

| P265GH | 0.20 | 0.40 | 1.40 | 0.025 | 0.020 | 410 | 410 | |

| EN10217-5 | P235GH | 0.16 | 0.35 | 1.20 | 0.025 | 0.020 | 360 | 360 |

| P265GH | 0.20 | 0.40 | 1.40 | 0.025 | 0.020 | 410 | 410 | |

| EN10219-1 | S235JRH | 0.17 | - | 1.40 | 0.040 | 0.040 | 360 | 360 |

| S275JOH | 0.20 | - | 1.50 | 0.035 | 0.035 | 410 | 410 | |

| S275J2H | 0.20 | - | 1.50 | 0.030 | 0.030 | 410 | 410 | |

| S355JOH | 0.22 | 0.55 | 1.60 | 0.035 | 0.035 | 470 | 470 | |

| S355J2H | 0.22 | 0.55 | 1.60 | 0.030 | 0.030 | 470 | 470 | |

| S355K2H | 0.22 | 0.55 | 1.60 | 0.030 | 0.030 | 470 | 470 | |

Tolerance of Outside Diameter and Wall Thickness

| Standard | Tolerance of Pipe Body | Tolerance of Pipe End | Tolerance of Wall Thickness | |||

| Out Diameter | Tolerance | Out Diameter | Tolerance | |||

| GB/T3091 | OD≤48.3mm | ≤±0.5 | OD≤48.3mm | - | ≤±10% | |

| 48.3<od≤273.1mm | ≤±1.0% | 48.3<od≤273.1mm< span=”" style=”padding: 0px; margin: 0px;”> | - | |||

| 273.1<od≤508mm | ≤±0.75% | 273.1<od≤508mm< span=”" style=”padding: 0px; margin: 0px;”> | -0.8~+2.4 | |||

| OD>508mm | ≤±1.0% | OD>508mm | -0.8~+3.2 | |||

| GB/T9711.1 | OD≤48.3mm | -0.79~+0.41 | - | - | OD≤73 | -12.5%~+20% |

| 60.3<od≤457mm | ≤±0.75% | OD≤273.1mm | -0.4~+1.59 | 88.9≤OD≤457 | -12.5%~+15% | |

| 508<od≤941mm | ≤±1.0% | OD≥323.9 | -0.79~+2.38 | OD≥508 | -10.0%~+17.5% | |

| OD>941mm | ≤±1.0% | - | - | - | - | |

| GB/T9711.2 | 60<od≤610mm | ±0.75%D~±3mm | 60<od≤610mm | ±0.5%D~±1.6mm | 4mm<wt<25mm | ±12.5%T~±15.0%T |

| 610<od≤1430mm | ±0.5%D~±4mm | 610<od≤1430mm | ±0.5%D~±1.6mm | WT≥25mm | -3.00mm~+3.75mm | |

| OD>1430mm | - | OD>1430mm | - | - | -10.0%~+17.5% | |

| SY/T5037 | OD<508mm | ≤±0.75% | OD<508mm | ≤±0.75% | OD<508mm | ≤±12.5% |

| OD≥508mm | ≤±1.00% | OD≥508mm | ≤±0.50% | OD≥508mm | ≤±10.0% | |

| API 5L PSL1/PSL2 | OD<60.3 | -0.8mm~+0.4mm | OD≤168.3 | -0.4mm~+1.6mm | WT≤5.0 | ≤±0.5 |

| 60.3≤OD≤168.3 | ≤±0.75% | 168.3<od≤610 | ≤±1.6mm | 5.0<wt<15.0 | ≤±0.1T | |

| 168.3<od≤610 | ≤±0.75% | 610<od≤1422 | ≤±1.6mm | T≥15.0 | ≤±1.5 | |

| 610<od≤1422 | ≤±4.0mm | OD>1422 | - | - | - | |

| OD>1422 | - | - | - | - | - | |

| API 5CT | OD<114.3 | ≤±0.79mm | OD<114.3 | ≤±0.79mm | ≤-12.5% | |

| OD≥114.3 | -0.5%~1.0% | OD≥114.3 | -0.5%~1.0% | ≤-12.5% | ||

| ASTM A53 | ≤±1.0% | ≤±1.0% | ≤-12.5% | |||

| ASTM A252 | ≤±1.0% | ≤±1.0% | ≤-12.5% | |||

Product Display

Product detail pictures:

Related Product Guide:

We always think and practice corresponding to the change of circumstance, and grow up. We purpose at the achievement of a richer mind and body as well as the living for stainless steel pipe company Manufacturer – SSAW Carbon SteelPipe Welded Steel Pipe – Future Metal , The product will supply to all over the world, such as: Bahrain, Macedonia, Serbia, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.

Write your message here and send it to us