Standard size of honing tube Factories – Hydraulic Cylinder Pipe High Precision Burnished Steel – Future Metal

Standard size of honing tube Factories – Hydraulic Cylinder Pipe High Precision Burnished Steel – Future Metal Detail:

The processing steps of the honing tube are

The steel pipes used in the hydraulic system are mainly stainless steel seamless pipes and ordinary seamless steel pipes. Although stainless steel seamless pipes have superior mechanical properties, they have not been widely used due to their high prices and low precision. Although ordinary seamless steel pipes are commonly used, they have poor mechanical properties and low precision. They usually go through a series of welding, trial assembly, pickling, alkali washing, water washing, long-term oil stringing, and leak testing before use. Complexity, time-consuming, unreliable materials, and the inability to completely remove the residues in the pipe, has become a major hidden danger for the entire hydraulic system to fail at any time. According to statistics, 70% of the failures in the hydraulic system are caused by this reason.

High-precision, precise and bright seamless steel pipes are special pipes for hydraulic systems.

1. Material selection: use metal bars with appropriate dimensions that meet national standards as raw materials for honing tubes;

2. Billet, free forging and heat treatment process: the raw material bar is processed by billet, free forging and heat treatment process;

3. Straightening: forging hammer straightening of the processed raw material bars;

4. Drilling deep holes: punch through holes of appropriate size in the raw material rods to make pipes;

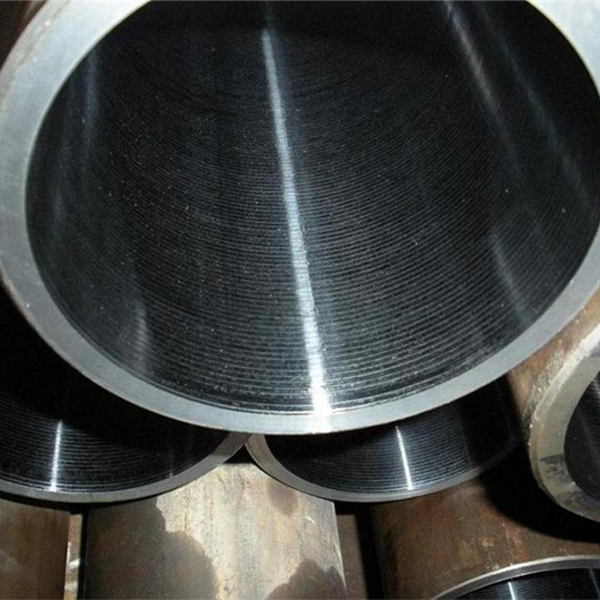

5. Honing: Use honing stone to honing the through hole of the pipe, so that the through hole of the pipe meets the size and processing accuracy requirements of the honing pipe;

6. Lathe outer circle planing: The outer wall and end surface of the pipe are lathe and planed, so that the outer diameter of the pipe meets the size and processing accuracy requirements of the honing pipe, and the production of the honing pipe is completed. Honing is an effective machining method for machining inner holes, which not only has high productivity, but also high machining accuracy.

There are six advantages

※ There is no oxide layer on the inner and outer walls of the steel pipe, which can be directly installed in the hydraulic system for use

※ Withstand high pressure without leakage

※ High precision

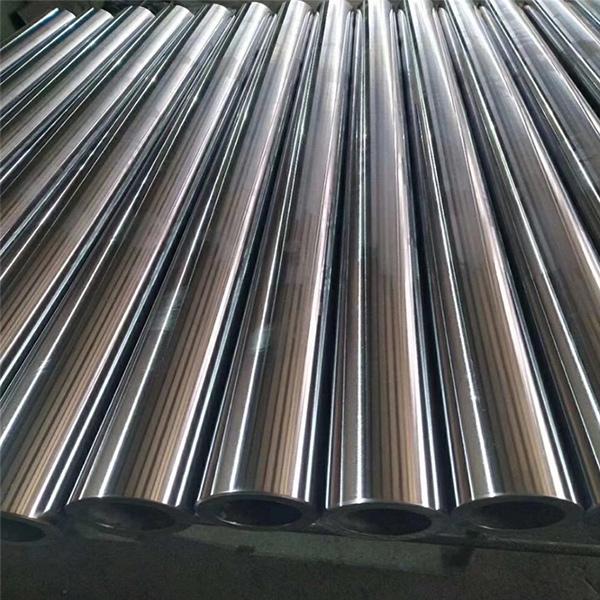

※ High finish

※ Cold bending does not deform

※ Flaring and flattening without cracks

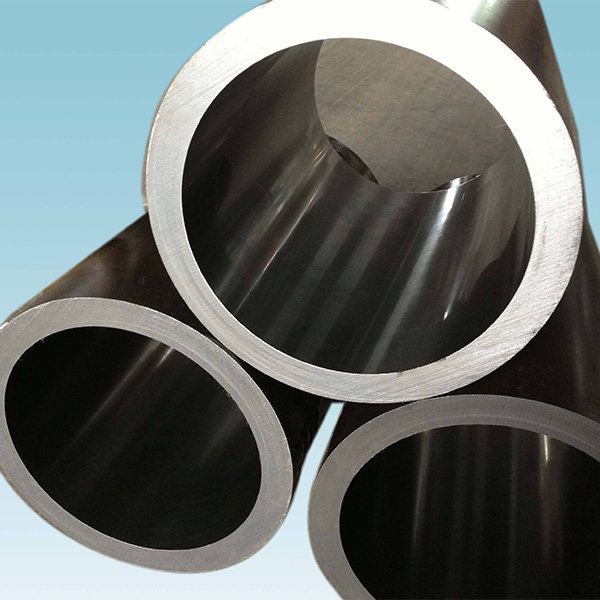

Product Display

Product detail pictures:

Related Product Guide:

Fast and great quotations, informed advisers to help you choose the correct solution that suits all your requirements, a short creation time, responsible top quality manage and distinct providers for paying and shipping affairs for Standard size of honing tube Factories – Hydraulic Cylinder Pipe High Precision Burnished Steel – Future Metal , The product will supply to all over the world, such as: Muscat, Croatia, Hungary, As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers, and establish a long term win-win business relationship. For more information, please contact us. And It is our great pleasure if you like to have a personally meeting in our office.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.